Refurbished Systems That Work Like New

To receive price quotes and estimates on Hot Runner Maintenance, Cleaning, or Repair Services simply call us at +1 (908) 281-0055 or visit the contact form below with details of your inquiry.!

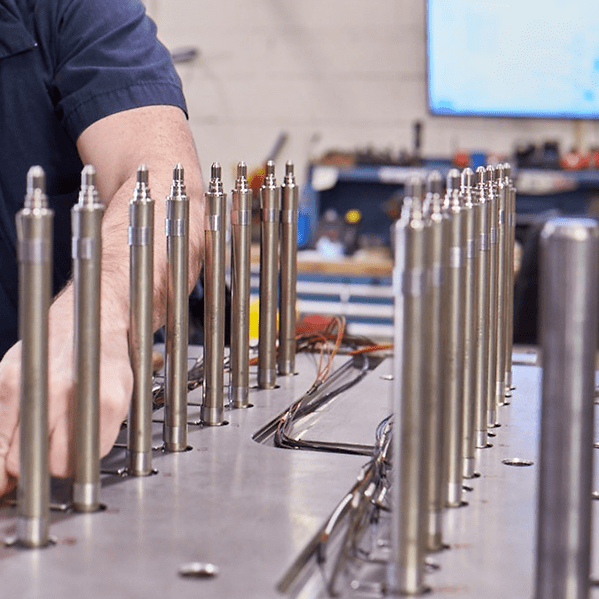

Hot Runner Maintenance

Reliable Maintenance for Hot Runner Systems

Effective maintenance of hot runner systems is critical for cost savings and efficient operations. Extend the life and performance of your hot runner systems while preserving resources. Unlike traditional OEM solutions, our specialized approach provides faster turnaround times, helping reduce downtime without compromising on quality.

A well-maintained hot runner system is key to consistent, high-quality output and reduced downtime. Regularly scheduled maintenance prevents material buildup, eliminates contamination, and improves flow precision – ultimately reducing waste and extending your system’s lifespan. At Polymer Cleaning Technology, we specialize in comprehensive hot runner maintenance services that keep your molding process performing at peak efficiency, saving you time and operational costs while ensuring flawless product quality with every cycle.

Invest in proper hot runner maintenance services today to avoid costly repairs in the future and ensure your production schedule.

Hot Runner Maintenance = Molding Efficiency

The continuous flow of molten plastic in hot runner systems can lead to the accumulation of residues that can cause blockages, uneven flow, and other issues. These residues can include:

- Carbon Buildup: Caused by the degradation of the resin at high temperatures.

- Degraded Resin: Resin that has been overheated or left in the system for extended periods.

- Contaminants: Foreign particles that may enter the system during material changes or through wear and tear.

If left unaddressed, these residues can lead to:

- Poor Part Quality: Inconsistent part weights, short shots, and defects.

- Increased Downtime: Frequent stops for cleaning and maintenance.

- Higher Maintenance Costs: More frequent and costly repairs.

- Production Delays: Reduced efficiency and slower production rates.

Benefits of Hot Runner Maintenance:

- Avoid Downtime: Identify issues before they lead to production stoppage.

- Extend Tool Life: Keep manifolds and heaters operating within design specs.

- Improve Consistency: Stable heating = consistent melt flow.

- Reduce Scrap & Start-Up Time: Fewer surprises during mold warm-up.

When You Should Schedule:

- During regular mold maintenance cycles

- After long production campaigns

- Following heater or sensor alarms

- Zones show uneven heating / response lag

- Anytime you clean the hot runner (ideal time to combine both services)

What We Service:

- Manifolds

- Heaters (band, cartridge, coil)

- Power Leads

- Thermocouples

- Wiring harnesses and connectors

- Seals and leak paths

- Flow channel integrity (visual and scope)

- Zone heating uniformity

- Temperature control response