Leak-Proof or Shutdown: The Real Cost of Faulty Seals in Hot Runner Systems

The smallest part that can stop your production cold.

O-rings and seal kits are often treated like afterthoughts. They’re small, cheap, and easily overlooked – until they fail. Then the fallout hits fast: resin leaks, pressure loss, damaged molds, contaminated parts, hours of cleanup, and costly downtime. One worn-out O-ring can halt an entire production line.

What are O-Rings and Seal Kits For?

O-rings in hot runner systems perform one critical job: maintain a pressure-tight, thermally resilient seal between interconnected components under intense stress.

They are typically used to:

- Seal connections between the manifold and nozzles

- Prevent molten resin leaks at gate interfaces

- Isolate thermal zones to prevent heat bleed or overheating

- Ensure pressure uniformity across the mold

These seals must endure:

- Continuous temperatures above 300°C (570°F)

- Injection pressures ranging from 20,000 to 30,000 psi

- Frequent thermal cycling and mechanical loading

- Chemical exposure from resins, cleaning agents, and additives

When these seals degrade, fail, or are improperly installed, production stops – fast.

Contact +1 (908) 281-0055 or sales@polymercleaning.com to discuss your Hot Runner Systems today! Experts in High Quality Hot Runner Parts, Repair, & Maintenance.

Common Causes of Seal Failure in Hot Runner Systems

Seal failure isn’t always dramatic at first. But even small degradation can compromise part quality and mold reliability.

🔥 Thermal Degradation

Heat hardens and cracks elastomers over time. Once an O-ring loses elasticity, it no longer seals properly.

⚙️ Compression Set

Under constant pressure, O-rings can flatten out and lose rebound force. They stop forming a tight seal even if they look intact.

🧪 Chemical Attack

Aggressive resins, cleaning solvents, or outgassing degrade materials that aren’t chemically compatible – especially if the wrong compound was selected.

📏 Improper Fit or Installation

An O-ring that’s slightly off in diameter or cross-section may get pinched, torn, or fail to compress properly, leading to micro-leaks or immediate failure.

🚫 Maintenance-Related Damage

Over-torquing, reusing aged seals, or contaminating the sealing surface can cause failures right after maintenance—undermining preventive efforts.

The Real Cost of Seal Failure

Let’s move from theory to real numbers.

Downtime

Depending on machine size, product value, and production volume, unplanned downtime from a seal failure can cost between $500 and $3,000 per hour. That includes:

- Lost cycles and parts

- Operator downtime

- Maintenance response time

- Disruption to delivery schedules

For example, a 24-cavity mold running a 30-second cycle loses 2,880 parts per hour. If each part is worth $0.80, one hour of downtime equals $2,304 in lost product alone.

Cleanup and Tool Damage

When resin leaks due to a failed seal:

- The molten material can carbonize and bond to the mold.

- Cleaning requires disassembly, heating, solvent baths, and sometimes mold plate resurfacing.

- Manifold replacement or repair can cost $10,000–$50,000 depending on design complexity.

Secondary Consequences

- Burnt or contaminated parts may be rejected, especially in medical or food-grade applications.

- Shot weight and cavity fill imbalance can result in warped or incomplete parts.

- Seal failure can lead to long-term mold damage if not caught early.

An Illustrative Scenario: The Potential Cost of a Seal Failure in Medical Molding

The following is a hypothetical but realistic example based on industry norms and known failure dynamics. It is intended to demonstrate how minor seal failures can lead to major consequences.

Scenario Summary

A Tier-2 medical molder is producing sterile syringe components using a 24-cavity hot runner mold. After approximately 500,000 cycles, a Viton (FKM) O-ring in the manifold degrades due to heat and loses sealing integrity during a weekend shift.

Consequences

- Unplanned downtime: 12 hours

- Machine output: 2,880 parts/hour

→ 34,560 parts lost - Part value: $0.80/each → $27,600 lost

- Scrap due to contamination: 11,000 parts → $11,000

- Cleanup & labor: $3,200

- Mold reconditioning: $2,500

🔻 Total Estimated Cost: ~$44,300

🧩 Cost of failed seal: ~$1.50

This fictional scenario echoes the financial dynamics outlined in actual seal performance studies and serves as a clear reminder: failure prevention is exponentially cheaper than failure recovery!

Real-World Data: DuPont Kalrez® Case Study

In a published cost-modeling study by DuPont and Gallagher Seals, a plant using standard elastomers like NBR or FKM needed 20–30 seal replacements per year, incurring:

- Initial costs: ~$87,800

- Downtime cost: ~$120,000

- Total system cost: $225,000–$295,000 annually

After switching to premium FFKM-based Kalrez® seals, annual replacements dropped to 8, and downtime decreased sharply:

- Initial cost (more expensive seals): ~$155,000

- Downtime cost: ~$48,000

- Total system cost: ~$215,000

- → Annual savings: $9,000–$80,000, depending on use case

Polymer Cleaning Technology Estimated Cost Impact

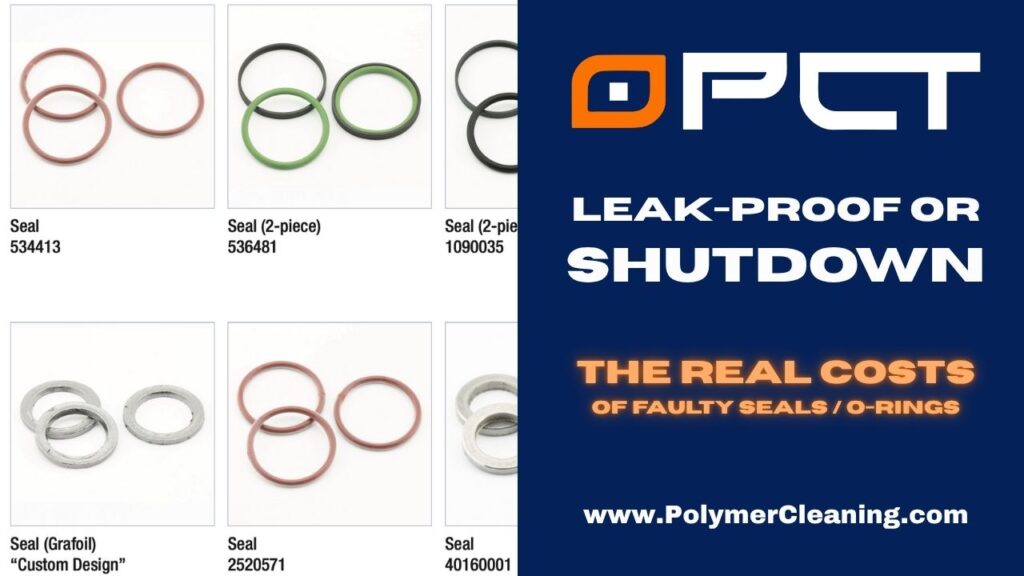

Polymer Cleaning Technology (PCT) offers a wide range of high-performance O-rings and sealing solutions compatible with all major hot runner systems, including Husky™, Mold-Masters™, Männer™, Milacron™, Nissei™, Sacmi™, Kortec™, and more. Their seal products are engineered specifically to withstand the heat, pressure, and chemical exposure common in high-cavity, high-speed injection molding environments.

Key Seal Technologies from PCT:

- Two-piece piston seal systems: Viton™ O-rings covered with graphite/Teflon® sleeves, or encapsulated in PTFE jackets, providing exceptional heat resistance and reduced wear.

- Vented stainless-steel seals: Designed to eliminate trapped gases and prevent resin leakage beneath nozzle housings.

- Grafoil® heat management seals: For precise thermal isolation in high-heat areas.

- Metal C-ring seals: Engineered for demanding, high-pressure applications requiring a rigid, leak-proof interface.

PCT emphasizes that proactive seal replacement, especially with enhanced piston and nozzle sealing systems, can significantly reduce unplanned downtime, improve part consistency, and extend overall mold and manifold lifespan.

Cost Modeling: Enhanced vs. Standard Seal Kits

Based on observed usage and maintenance data from industry-standard molding operations:

| Metric | Standard Viton® Seals | PCT Enhanced Sealing Systems |

|---|---|---|

| Annual seal replacements | ~30 | ~8–10 |

| Downtime incidents per year | Frequent | Minimal |

| Leak-related mold cleanings | High | Rare |

| Estimated annual seal-related cost* | $250,000–$300,000 | $170,000–$200,000 |

| Estimated annual savings | — | $80,000–$100,000 |

*Includes seal replacement, downtime, labor, part scrap, and repair estimates based on typical hot runner operations.

By upgrading to premium piston and nozzle seal solutions with PCT, injection molders can reduce both maintenance frequency and the high hidden costs tied to standard seal failure – turning a $1.50 part into a high-leverage point for plant-wide performance.

How to Prevent Seal-Related Downtime

Prevention beats emergency repair—every time.

Best Practices:

- Replace O-rings on a fixed cycle schedule, not just when they “look bad”

- Match seal material to:

- Resin type (chemical compatibility)

- Mold temperature (thermal tolerance)

- Injection pressure (mechanical resilience)

- Train technicians on proper seal installation and inspection

- Always use manufacturer-recommended kits—don’t mix parts

- Never reuse seals during PM, even if they “look fine”

PM Checklist Guide:

| Inspection Item | Recommended Action |

|---|---|

| Manifold seals | Replace every 250,000–500,000 cycles |

| Nozzle seals | Inspect for discoloration/cracking |

| Seal grooves | Clean and polish to prevent seating issues |

| Backup rings | Replace if flattened, torn, or discolored |

| Installation torque | Use spec tools, avoid over-tightening |

Signs Your Seals Are Headed for Failure

- Burn marks or resin streaks near gates

- Variations in shot size or cavity fill

- Flattened, hardened, or brittle O-rings during teardown

- Discoloration or cracking on elastomer surfaces

- Visible signs of resin leaking around manifold plates or nozzle tips

These symptoms often emerge quietly—and by the time they’re loud, it’s already too late.

Invest in Quality, Reap Long-Term ROI

Premium seals cost more up front—but pay off fast when you consider:

- Fewer emergency stoppages

- Reduced technician overtime

- Fewer defective parts

- Faster mold changeovers

- Longer mold and manifold lifespan

ROI Snapshot (Modeled):

| Metric | Standard Seals | Premium Seals (FFKM) |

|---|---|---|

| Annual replacements | 30 | 8 |

| Downtime cost/year | ~$180,000 | ~$48,000 |

| Total seal-related cost | ~$294,000 | ~$215,000 |

| Estimated annual savings | — | $79,000 (27%) |

(Adapted from DuPont Kalrez ROI model)

Pay Attention to the Parts You Can’t See

Seal kits and O-rings may be small, but they’re mission-critical. Ignoring them leads to production shutdowns, scrap, lost revenue, and damaged tooling. But with proper material selection, replacement cycles, and quality assurance, you can make seal-related failures rare—and reduce total system cost.

Don’t let a $1.50 part cost you $50,000.

Take control of your seals, and you’ll take control of your uptime.

Polymer Cleaning Technology: Leading the Way in Hot Runner Services and Parts

With a reputation for precision and reliability, PCT helps manufacturers keep their hot runner systems operating at peak performance.

Services Offered

Hot Runner Cleaning

Specialized chemical-free cleaning systems remove polymer residue without damaging metal surfaces.

Hot Runner Maintenance

Thorough Inspection, Testing, Analysis, Assembly, and Comprehensive Reports.

Preventive Maintenance Programs

Tailored service schedules to suit production environments.

Component Repair & Refurbishment

Includes manifolds, heaters, nozzles, and temperature control systems.

Reverse Engineering & Custom Parts

Solutions for hard-to-find or discontinued OEM parts.

Parts Inventory

- Nozzle Tip Insulators

- Heaters (coils, bands, cartridges)

- Thermocouples

- Nozzle Tips

- Valve Pins

- Nozzle Housings

- Sealing kits

*This information is to be used as a general guideline only. Speak to your system manufacturer directly for verified information regarding your Hot Runner System.

Find this information useful? Share with friends & colleagues:

Contact Information:

Polymer Cleaning Technology, Inc.

sales@polymercleaning.com

+1 (908) 281-0055