Hot Runner Parts: A Brief Guide to Critical Hot Runner Components

Hot runner systems are integral to the efficiency and quality of plastic injection molding processes. By maintaining the molten state of plastic within the mold, these systems eliminate the need for runners, reduce waste, and enhance cycle times. A comprehensive understanding of hot runner components is essential for optimizing performance and ensuring product quality. This brief guide explains the critical parts of hot runner systems, including nozzle tip insulators, nozzle housings, nozzle heaters, thermocouples, and valve pins.

Contact +1 (908) 281-0055 or sales@polymercleaning.com to discuss your Hot Runner Systems today! The experts in Hot Runner Parts, System Repair, and Maintenance for all OEM.

Nozzle Tip Insulators

Nozzle tip insulators are pivotal in maintaining thermal efficiency within hot runner systems. Crafted from high-performance materials like Vespel SP1, these insulators effectively minimize heat loss at the nozzle tip, ensuring consistent melt temperature and preventing premature solidification of the plastic material. This consistency is crucial for achieving uniform part quality and reducing defects. Nozzle tip insulators serve as a barrier between the heated nozzle and the mold, preventing excessive heat transfer that could lead to molding inconsistencies. They are designed to withstand prolonged exposure to high temperatures and pressures, making material selection critical to their performance. Some advanced insulators feature composite structures that provide superior durability and thermal insulation, further improving process efficiency. Leading manufacturers such as Husky, Mold-Masters, and Milacron offer nozzle tip insulators tailored to their specific systems, ensuring compatibility and optimal performance.

Nozzle Heaters

Maintaining the appropriate temperature of the nozzle is critical for the consistent flow of molten plastic. Nozzle heaters are designed to provide uniform heating, preventing issues like cold spots that can lead to defects in the molded parts. Advanced designs, such as integrally heated sprue bushings, offer enhanced heat transfer and uniformity. These heaters are constructed with high-grade materials to ensure durability and longevity, even under continuous operation. Nozzle heaters come in various forms, including cartridge heaters, coil heaters, and mica band heaters, each suited for different applications and system configurations. Efficient heat transfer is crucial in preventing material degradation while ensuring the polymer maintains its proper viscosity throughout the injection process. In addition to precise temperature control, modern nozzle heaters often incorporate advanced insulation layers to minimize energy consumption and improve overall system efficiency. Routine inspection and maintenance of nozzle heaters help prevent failures that could lead to downtime and production losses.

Nozzle Housings

Nozzle housings serve as the structural framework for the nozzle assembly, providing support and alignment for other components. They are engineered to withstand high pressures and temperatures inherent in injection molding processes. Precision in the design and manufacturing of nozzle housings is essential to prevent issues such as leakage or misalignment, which can compromise the molding process. Typically made from hardened steel or specialized alloys, nozzle housings provide strength and stability while maintaining precise thermal control. The internal geometry of the housing is carefully designed to optimize the flow of molten plastic, reducing shear stress and ensuring consistent material distribution. Properly engineered nozzle housings help prevent thermal degradation of polymers, minimizing defects such as burn marks or material degradation. Companies like Polymer Cleaning Technology (PCT) offer a range of nozzle housings compatible with various OEM systems, ensuring seamless integration and reliability.

Thermocouples

Thermocouples are temperature-sensing devices that monitor and control the heat within hot runner systems. Accurate temperature measurement is vital for maintaining the molten state of plastic and ensuring consistent part quality. J-type thermocouples are commonly used in these systems due to their reliability and precision. A thermocouple functions by generating a voltage proportional to the temperature difference between its two junctions, allowing for real-time temperature monitoring. Properly placed thermocouples provide critical feedback to the hot runner controller, enabling adjustments to maintain consistent heating profiles. Thermocouples must be resistant to contamination and wear, as exposure to high temperatures and molten plastic can degrade their accuracy over time. Some advanced thermocouples incorporate protective sheathing made of stainless steel or ceramic to extend their lifespan and ensure continued accuracy. PCS Company provides a variety of OEM replacement thermocouples designed to meet the specific requirements of different hot runner systems, ensuring accurate temperature control and optimal performance.

Valve Pins

Valve pins are crucial components in valve-gated hot runner systems, controlling the flow of molten plastic into the mold cavity. These pins move in a precise, controlled manner to open and close the flow channels, preventing drooling, stringing, and other molding defects. High-performance valve pins are often made from hardened tool steel or specialized coatings to withstand wear and ensure longevity. The movement of valve pins is typically driven by pneumatic or hydraulic actuators, providing precise control over the injection process. Proper valve pin alignment and lubrication are essential to avoid excessive wear and ensure smooth operation. In high-cavitation molds, valve pins must operate in perfect synchronization to prevent uneven filling and dimensional inconsistencies in molded parts. Some modern valve pins feature advanced coatings such as titanium nitride or DLC (diamond-like carbon) to reduce friction and enhance wear resistance. Proper maintenance and timely replacement of valve pins are essential for maintaining optimal injection molding performance. Companies like Polymer Cleaning Technology offer both standard and custom valve pins tailored to various hot runner systems.

Polymer Cleaning Technology: A Leader in Hot Runner Parts and Custom Solutions

Contact +1 (908) 281-0055 or sales@polymercleaning.com to discuss your Hot Runner Systems today! Experts in Hot Runner System Repair and Maintenance for all OEM.

Polymer Cleaning Technology (PCT) stands out as a premier provider of high-quality hot runner part sales and services across the globe. With an extensive inventory that includes nozzle tips, insulators, thermocouples, heaters, valve bushings, and more, PCT caters to a wide range of OEM systems, including Husky, Mold-Masters, Männer, SIPA, SACMI, Yudo, Milacron and more. A commitment to quality ensures that each component meets or exceeds OEM specifications, providing customers with reliable and cost-effective solutions for over 30 years.

Beyond offering standard components, PCT excels in producing custom hot runner parts tailored to specific customer requirements. Utilizing advanced engineering and manufacturing techniques, PCT can reverse engineer and fabricate components that are no longer available or need modification to enhance performance. This capability allows customers to maintain and upgrade their existing systems without the need for complete overhauls, resulting in significant cost savings and minimized downtime.

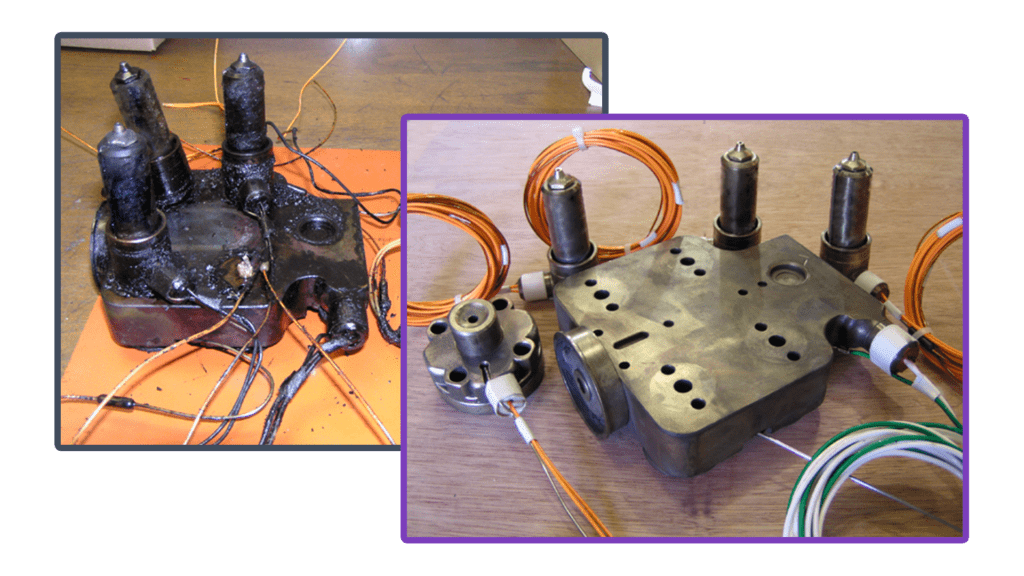

In addition to parts manufacturing, PCT provides comprehensive maintenance and repair services for hot runner systems. Our expertise in manifold cleaning, nozzle heater repairs, and component refurbishments ensures that injection molding operations run smoothly and efficiently. By partnering with PCT, manufacturers can extend the lifespan of their equipment, reduce operational costs, and maintain high-quality production standards.

Understanding the components of hot runner systems is essential for optimizing the plastic injection molding process. Key parts such as nozzle tip insulators, nozzle housings, nozzle heaters, thermocouples, and valve pins play critical roles in ensuring efficiency, consistency, and quality in molded products. Polymer Cleaning Technology is able to provide invaluable support by offering high-quality standard and custom components, as well as maintenance services, enabling manufacturers to achieve optimal performance and longevity from their hot runner systems.

*This information is to be used as a general guideline only. Speak to your system manufacturer directly for verified information regarding your Hot Runner System.

For more in-depth insights into hot runner parts, visit us at www.PolymerCleaning.com, or give us a call at (908) 281-0055.

Find this information useful? Share with friends & colleagues:

Contact Information:

Polymer Cleaning Technology, Inc.

sales@polymercleaning.com

+1 (908) 281-0055