Burn Off Ovens

Industrial Tool Cleaning Systems

ECO BURN OFF OVENS ARE THE IDEAL SOLUTION FOR ALL TOOL CLEANING NEEDS

PCT offers a wide range of burn off oven sizes to meet all your tool cleaning needs.

Say goodbye to outsourcing and shipping delays! Save time, cut costs, and go green with an in-house industrial cleaning oven. This state-of-the-art tool cleaning system is designed to effectively remove contaminants and residues from tools and parts, delivering an efficient, eco-friendly cleaning process.

- AUTOMATIC INDUSTRIAL FURNACE SYSTEMS

- LOW LABOR COSTS

- PRECISE TEMPERATURE CONTROL TO GUARANTEE NO TOOL DAMAGE

- REMOVES ALL RESINS

- EASILY CLEANS FULLY ASSEMBLED TOOLING:

Hot Runners, Blown Film Dies, Fully Assembled Spin Packs

- FAST CYCLE TIMES (6 – 12 Hours)

- NO SMOKE, NO SMELL GUARANTEED BY INTEGRAL AFTERBURNER

Burn Off Ovens are an efficient, self-contained cleaning solution for your business. Advanced combustion technology ensures all residues are safely burned off while maintaining a low environmental footprint. Perfect for heavy-duty industries that need reliable, quick, and safe cleaning solutions.

Popular Burn Off Oven Models

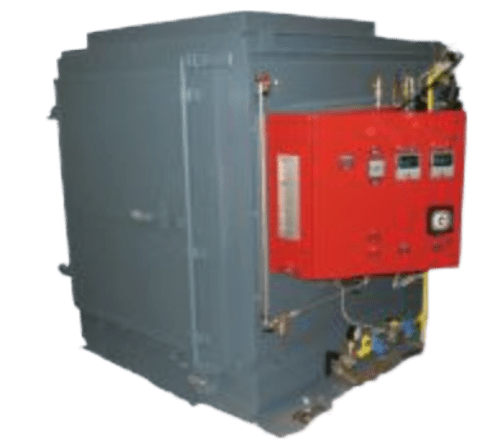

MODEL EB-13

PERFECT FOR LIGHT DUTY USE IN THE TOOL ROOM

TOOL CLEANING APPLICATIONS:

SMALL HOT RUNNERS, NOZZLE TIPS, AND MISCELLANEOUS INJECTION MOLDING HARDWARE.

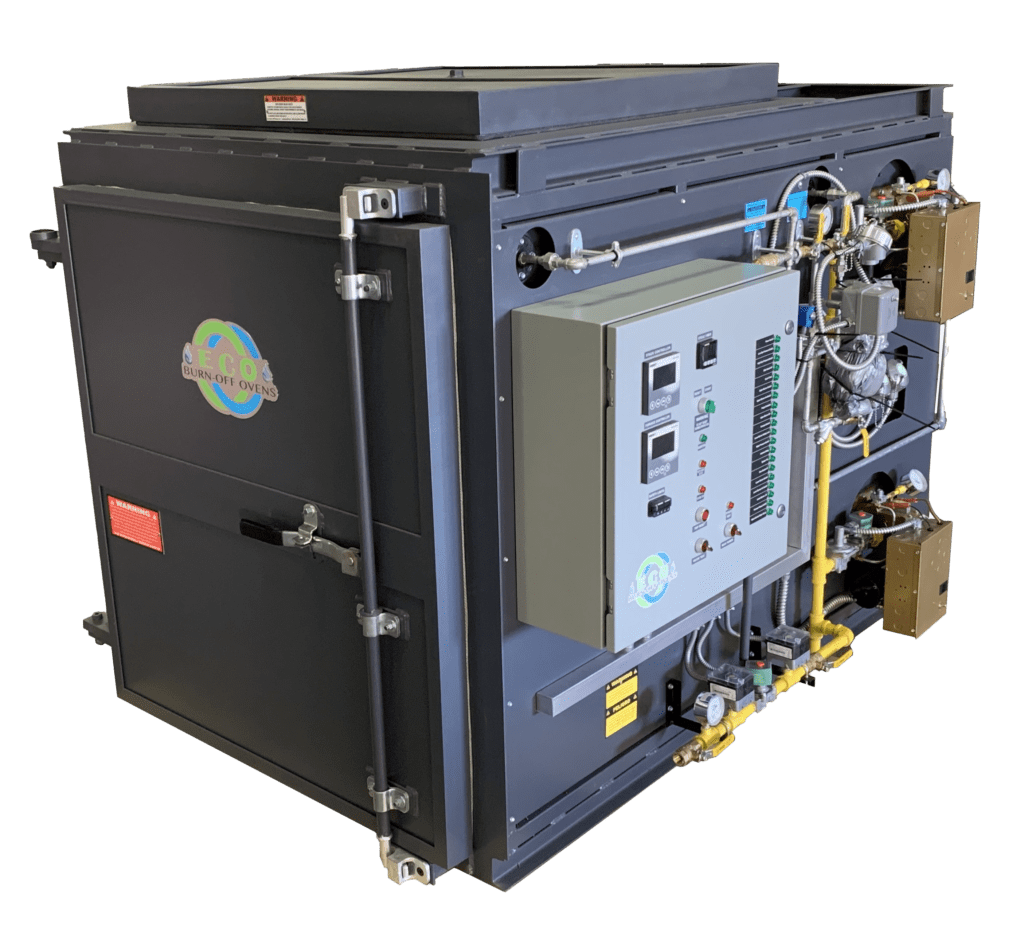

MODEL EBIG-52

THE WORKHORSE MODEL

TOOL CLEANING APPLICATIONS:

LARGE HOT HALVES, FULLY ASSEMBLED BLOWN FILM DIES AND FIBER SPIN PACKS

An In-House Tool Cleaning System eliminates the need for outsourcing, saving you time and money while ensuring better control over the cleaning process. Whether paint racks, molds, hot halves or component cleaning, thermal stripping ovens provide a reliable and thorough solution to meet your needs.

Investing in an ECO Burn-Off Oven streamlines your operations, extends the life of your tools, and enhances productivity. Discover the difference an advanced tool cleaning system can make for your business today!