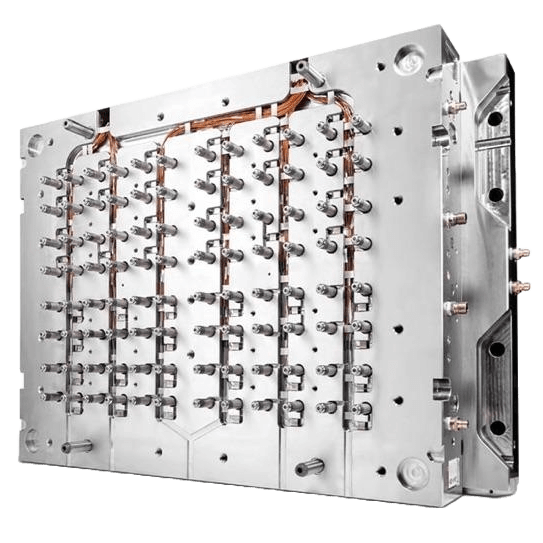

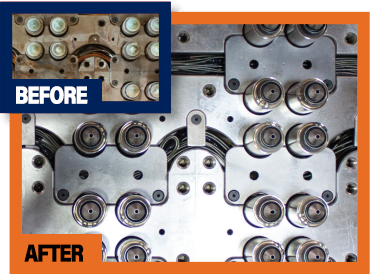

Refurbished Systems That Work Like New

To receive price quotes and estimates on Hot Runner Repair, Maintenance, or Refurbishment Services simply call us at +1 (908) 281-0055 or visit the contact form below!

Hot Runner Cleaning

Cost-Effective Cleaning Solutions for Hot Runner Systems

Effective cleaning of hot runner systems is critical for cost savings and efficient operations. Extend the life and performance of your hot runner systems while preserving resources. Unlike traditional OEM solutions, our specialized approach provides faster turnaround times, helping reduce downtime without compromising on quality.

A clean hot runner system is key to consistent, high-quality output and reduced downtime. Regular cleaning and maintenance prevent material buildup, eliminate contamination, and improve flow precision—ultimately reducing waste and extending your system’s lifespan. At Polymer Cleaning Technology, we specialize in thorough cleaning services that keep your hot runner systems performing at peak efficiency, saving you time and operational costs while ensuring flawless product quality with every cycle.

Hot Half Cleaning • Hot Runner Manifold Cleaning • Husky Hot Runner Cleaning • Mold-Masters Cleaning

Clean Hot Runner Systems = Maximized Output

Restore your hot runner to factory-grade performance with professional Hot Runner Cleaning services.

We remove carbon buildup, degraded resin, and pigment residue from manifolds, nozzles, and gates to eliminate contamination, improve part quality, and reduce downtime.

Whether you’re running high-cavitation molds, fast-cycle packaging tools, or precision medical components, our thermal-based cleaning process is the trusted choice for molders who can’t afford inconsistency.

The Polymer Cleaning Technology Process

100% Safe

Hot Runner Manifold Cleaning by PCT will not damage/distort the manifold, or alter the surface finish.

Quick & Easy

We’ll clean your Hot Runner on your schedule.

Most jobs are processed within 24 hours, localized same-day service is also available.

Thorough & Detailed

Complete removal of resin from the flow channels including all burned and degraded material.

Ideal for removing metal from flow channels.

Specially Adapted

Special adaptation to work on high-temperature resins like ULTEM and LIQUID CRYSTAL.

We can effectively clean all manifolds processing nylons up to 40% glass filled.

Hot Runner Cleaning Benefits

Improve Color Change Time: Removes pigment residues that cause streaking.

Reduce Downtime: A clean system starts faster and runs consistently.

Protect Tool Life: Eliminate the need for aggressive purging or mechanical cleaning.

Enhance Part Quality: Fewer defects, better consistency, and improved flow balance.

OEM We Service

HUSKY, Männer, Mold-Masters, MHT, Otto Hofstetter, Kortec, Sipa, Sacmi, Nissei ASB, Milacron, Yudo and more!