When a hot runner system is not matched correctly to the resin being used, it can lead to a range of issues: product defects, reduced cycle times, and increased maintenance costs. One of the most overlooked but critical aspects in the selection or servicing of systems is hot runner manifold material compatibility.

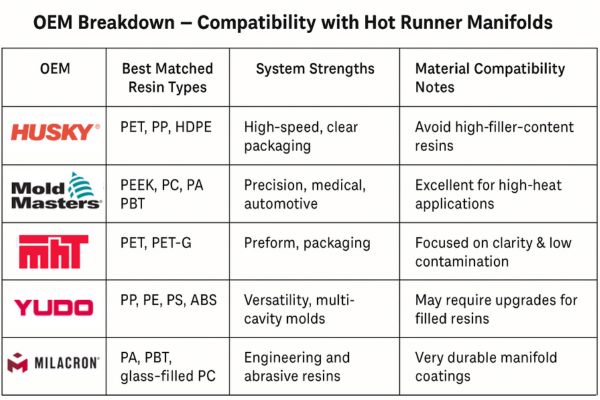

Choosing the right manifold setup based on the resin type is not one-size-fits-all. Each OEM – be it Husky, Mold-Masters, MHT, Yudo, Milacron or any other – designs their hot runners with specific materials, coatings, and geometries that cater to particular resin characteristics. Understanding how these systems interact with different thermoplastics is key to optimizing performance, reducing downtime, and extending the life of the system.

Contact +1 (908) 281-0055 or sales@polymercleaning.com to discuss your Hot Runner Systems today! Experts in Hot Runner System Repair and Maintenance for all OEM.

Hot Runner Manifold Material Compatibility Matters

Thermal Degradation

Certain resins, like PET and PVC, are especially sensitive to heat. If the hot runner cannot maintain precise temperature control or if the resin is held at temperature for too long (high residence time), the material can degrade. This results in black specks, discoloration, or poor mechanical performance in the molded parts.

Shear Sensitivity

Shear-sensitive resins, such as bioresins or PVC, degrade when subjected to high shear forces during flow. If the manifold channels are too narrow or have sharp transitions, the shear stress increases, potentially altering the polymer’s molecular structure and degrading the final product quality.

Manifold Wear or Erosion

Filled materials, particularly those containing glass or mineral reinforcements, are highly abrasive. Over time, they can erode internal surfaces of the manifold, leading to leaks, inconsistent flow, or complete system failure. Material selection for the manifold – like using hardened tool steels or wear-resistant coatings – can mitigate this issue.

Contamination and Color Streaking

Dead spots in the manifold where the flow is stagnant can trap degraded resin or color additives. These areas become sources of contamination, causing streaks or specks in the molded parts. This is particularly problematic in applications requiring high clarity or color precision, such as medical devices or packaging.

Flow Consistency and Thermal Uniformity

Even heat distribution and uniform flow are crucial for consistent part quality. Any variation in temperature across the manifold can lead to differences in melt viscosity, which in turn causes uneven filling, short shots, or warpage. High-end systems mitigate this through precision heating zones and balanced flow paths.

Key Factors That Influence Manifold Material Compatibility

Thermal Conductivity and Heat Transfer Behavior

Hot Runner Manifold Material directly affects how heat is transferred to the resin. Materials like copper alloys offer excellent thermal conductivity, which helps maintain uniform melt temperature. However, these materials may not be suitable for abrasive resins. High-grade steels, while less conductive, are more durable and better suited for long runs and abrasive materials.

Corrosion and Abrasion Resistance

Some resins release corrosive gases during processing, especially those containing halogens or certain additives. Stainless steels or nickel-based alloys are more resistant to this kind of chemical attack. For abrasive resins, like glass-filled nylons, materials with high surface hardness or special coatings (e.g., titanium nitride) help extend the manifold’s operational life.

Flow Channel Geometry Relative to Viscosity and Filler Content

High-viscosity resins or those filled with glass require flow paths that minimize resistance and shear. Manifolds must be designed with larger or more streamlined channels to accommodate these characteristics. Sudden changes in direction or diameter can lead to filler drop-out or clogging.

Pressure Tolerance of Manifold Designs

Injection pressures vary greatly depending on the resin. Systems processing high-viscosity or filled materials often require higher pressures, which means the manifold must be structurally robust and tightly sealed. Poor design or material choice here can lead to leaks and mechanical failure.

Dead Spots and Residence Time in Relation to Temperature-Sensitive Resins

Manifolds should be designed to eliminate zones where resin can sit without movement. These “dead spots” can lead to thermal degradation, particularly with sensitive materials like PET or PVC. Manifolds with optimized flow paths and minimal corners reduce residence time and improve quality.

Common Resin Types and Their Demands on Hot Runner Manifolds

High-Temperature Materials (PEEK, PSU, LCP)

These engineering resins require hot runners that can operate at temperatures above 300°C. Manifolds need to be made of high-performance alloys with excellent thermal stability and resistance to creep. They must also be insulated to maintain consistent processing conditions.

Filled Materials (Glass or Mineral Filled Nylons, Polycarbonates)

These are among the most abrasive resins. They demand robust manifold materials, such as hardened steels or those treated with wear-resistant coatings. Flow channels should be optimized to prevent buildup and ensure consistent filler dispersion.

Shear-Sensitive Resins (PVC, Certain Bioresins)

These require gentle handling through large-radius flow paths and smooth transitions to reduce shear stress. The manifolds also need to be corrosion-resistant due to the chemical nature of some of these resins.

Standard Resins (PP, PS, ABS, PE, PET)

These commonly used thermoplastics are less demanding and can be run through a wider variety of manifold materials. However, specific applications (like food-grade PET or optical-grade PS) may still require high-clarity, contamination-resistant manifold designs.

Resins used by Leading Hot Runner Systems

Husky (e.g., HyPET, UltraSync)

Husky hot runner systems are engineered for high-performance applications, particularly in the packaging sector. Known for their precision and speed, Husky’s UltraSync and HyPET systems are optimized for processing PET, PP, and HDPE resins. These systems provide exceptional thermal control and are designed to minimize residence time—crucial for maintaining the optical clarity of PET preforms. Husky also incorporates its patented Ultra Helix valve gate technology, which improves gate quality and part consistency. While ideal for high-speed, high-volume production of clear packaging products, Husky systems may require customization or coating upgrades when processing highly abrasive or filled engineering materials.

- Best Matched Resin Types: PET, PP, HDPE

- System Strengths: Optimized for high-speed, high-clarity applications, especially in packaging.

- Material Compatibility Notes: Designed for clarity and throughput; not ideal for highly abrasive or filled resins.

Husky emphasizes that resin thermal uniformity and minimal residence time are key for PET clarity, a principle underlying their Ultra Helix valve‑gate design.

Mold-Masters (e.g., Fusion-Series G2, Summit, Dura+)

Mold-Masters offers one of the most versatile hot runner portfolios in the industry, with solutions tailored for high-performance, high-temperature, and shear-sensitive resins. The Fusion-Series G2 is particularly strong in automotive and large-part applications, capable of handling PA, PBT, and glass-filled materials. The Summit Series focuses on precision molding for medical and electronic parts, making it suitable for high-temperature resins like PEEK and PC. Mold-Masters systems utilize advanced thermal management technologies and field-replaceable components to minimize downtime and simplify maintenance. Their systems are designed for longevity and can be upgraded easily to adapt to evolving material demands or tighter process tolerances.

- Best Matched Resin Types: PEEK, PC, PA, PBT

- System Strengths: Handles a wide range of resins; Summit Series excels in medical and high-precision applications.

- Material Compatibility Notes: Highly capable of processing high-heat, shear-sensitive, and filled materials.

Mold‑Masters’ MasterCARE® program outlines how proactive wear‑resisting coatings and periodic component replacement significantly reduce downtime and maintain performance consistency.

MHT (e.g., MHT for PET preforms)

MHT specializes in hot runner solutions for PET and PET-G preforms, where clarity, speed, and hygiene are critical. These systems are designed to maintain thermal uniformity and eliminate dead spots that could degrade resin. MHT manifolds and nozzles often incorporate advanced insulation and flow channel designs that reduce residence time and thermal stress. These characteristics make MHT ideal for use with both virgin and recycled PET materials. While they excel in high-volume preform production, MHT systems are not typically engineered for abrasive or high-temperature engineering plastics, and retrofitting may be limited based on mold compatibility.

- Best Matched Resin Types: PET, PET-G

- System Strengths: Specialized in preform applications with an emphasis on optical clarity and minimal contamination.

- Material Compatibility Notes: Ideal for short residence times and recycled materials.

Milacron (includes Mold-Masters Dura+)

Milacron’s hot runner solutions, including the Dura+ series through its Mold-Masters brand, are engineered for robustness and compatibility with high-performance resins. These systems are especially well-suited for processing glass-filled nylons, polycarbonate, and other abrasive or high-viscosity thermoplastics. Milacron emphasizes wear resistance and longevity, incorporating hardened steels and advanced sealing solutions to reduce maintenance needs. Their hot runners often support complex part geometries and high-pressure molding scenarios, making them a good fit for automotive, industrial, and appliance sectors. Milacron systems can be serviced and upgraded to accommodate evolving resin requirements, helping manufacturers get more life from their tooling investment.

- Material Compatibility Notes: Strong coatings and durable materials make it suitable for abrasive, engineering-grade thermoplastics.

- Best Matched Resin Types: PA, PBT, glass-filled PC

- System Strengths: Engineered for tough, high-performance resins.

Yudo

Yudo systems are known for their adaptability and cost-efficiency across a broad range of commodity and engineering-grade resins. Commonly used with PP, PE, PS, and ABS, Yudo manifolds are popular in multi-cavity molds and general-purpose applications. Their modular hot runner systems support high-volume production with ease. While Yudo provides configurations for filled and technical polymers, users processing abrasive materials or high-temperature engineering resins may need to incorporate additional upgrades such as wear-resistant coatings or reinforced tips. Yudo’s strength lies in its scalable design and wide compatibility, making it a flexible option for molders with diverse material needs.

- Best Matched Resin Types: PP, PE, PS, ABS

- System Strengths: Flexible and suitable for general-purpose and multi-cavity applications.

- Material Compatibility Notes: Versatile but may require upgrades for abrasive or high-temperature resins.

Engineering & Servicing Considerations

Selecting or Updating Hot Runner Manifolds

When processing aggressive resins, it’s vital to select manifolds made from materials that resist corrosion and wear. Retrofitting older systems with updated steels or coatings can allow them to process more challenging materials without premature failure.

Retrofitting Hot Runner Manifolds to Run New Materials

As manufacturers evolve product lines, they often need to process new resin types in existing molds. This requires evaluating whether the current hot runner can handle the new material’s thermal and flow demands. Modifications might include enlarging flow channels, upgrading heaters, or applying protective coatings.

Retrofitting also involves compatibility checks between valve gate components, seals, and the thermal expansion properties of the manifold materials. When running more abrasive or high-viscosity materials, upgrading gate bushings, nozzle tips, and thermal control elements may be necessary. The goal is not just to make the system work, but to optimize it for consistency, output quality, and longevity.

Cleaning Procedures Tailored to Specific Resin Residue

Cleaning procedures vary widely depending on the resin. PET, for example, can carbonize, requiring frequent purging and maintenance. Glass-filled materials can leave abrasive residue that necessitates mechanical cleaning. Tailoring maintenance procedures ensures better long-term performance and reduces downtime.

Upgrading System Components and Preventive Maintenance

Modernization isn’t limited to new molds, existing systems can often be upgraded with newer technology. For instance, switching to next-generation heaters, advanced temperature controllers, or integrating real-time diagnostics can bring an aging hot half back in line with today’s production standards.

Preventive maintenance programs are also crucial. Periodic bore-scope inspections, seal replacement, and heater resistance checks catch small problems before they cause costly shutdowns. Investing in a maintenance routine, whether through in-house technicians or third-party service experts, extends the life of your manifold and ensures it continues performing under evolving resin requirements.

Polymer Cleaning Technology: Leading the Way in Hot Runner Services and Parts

With a reputation for precision and reliability, PCT helps manufacturers keep their hot runner systems operating at peak performance.

Services Offered

Hot Runner Cleaning

Specialized chemical-free cleaning systems remove polymer residue without damaging metal surfaces.

Hot Runner Maintenance

Thorough Inspection, Testing, Analysis, Assembly, and Comprehensive Reports.

Preventive Maintenance Programs

Tailored service schedules to suit production environments.

Component Repair & Refurbishment

Includes manifolds, heaters, nozzles, and temperature control systems.

Reverse Engineering & Custom Parts

Solutions for hard-to-find or discontinued OEM parts.

Parts Inventory

- Nozzle Tip Insulators

- Heaters (coils, bands, cartridges)

- Thermocouples

- Nozzle Tips

- Valve Pins

- Nozzle Housings

- Sealing kits

Hot Runner Manifold Material Compatibility is not just a technical detail, it’s a performance-critical factor that affects every aspect of injection molding.

From thermal degradation and wear to color consistency and cycle time, the right match between resin and manifold can mean the difference between efficient production and chronic maintenance issues. Understanding the specific demands of each resin type allows manufacturers to select or retrofit systems that meet those needs without compromise.

Each OEM brings unique strengths to the table, and aligning those capabilities with your material requirements is key to long-term reliability. Whether you’re producing PET preforms at high speed, molding precision medical parts, or running abrasive engineering resins, informed decisions on hot runner compatibility directly impact output quality and operational costs. As materials evolve and production goals shift, so too must the approach to manifold selection and service. Investing in compatibility upfront saves time, money, and headaches down the line.

*This information is to be used as a general guideline only. Speak to your system manufacturer directly for verified information regarding your Hot Runner System.

Find this information useful? Share with friends & colleagues:

Contact Information:

Polymer Cleaning Technology, Inc.

sales@polymercleaning.com

+1 (908) 281-0055